A DOT inspection, also known as a commercial motor vehicle (CMV) inspection. An inspection involves a thorough examination performed by the U.S. Department of Transportation (DOT) or its authorized agents to ensure that commercial vehicles are safe to operate on the roads. These inspections are crucial for maintaining road safety and preventing accidents involving large trucks and other commercial vehicles.

Here's a breakdown of key points about DOT inspections:

- Purpose: To check if commercial vehicles comply with safety standards and are in good working order.

- DOT inspections apply to: Commercial vehicles (large trucks, buses, etc.) weighing over 10,000 pounds.

- Frequency: Mandatory annual inspections, with additional levels of inspections possible under certain circumstances.

There are more in-depth subjects about what a DOT inspection is. Let's understand specific inspection procedures or aspects.

What is the DOT checklist?

The exact "DOT checklist" can refer to a few different things, depending on the specific context:

1. DOT Inspection Checklist

This is the most common meaning and refers to the list of items a DOT inspector uses to examine a commercial motor vehicle (CMV) during an inspection. It covers various aspects of a vehicle only inspection, including:

Driver qualifications: License, medical examiner's certificate, hours of service record.

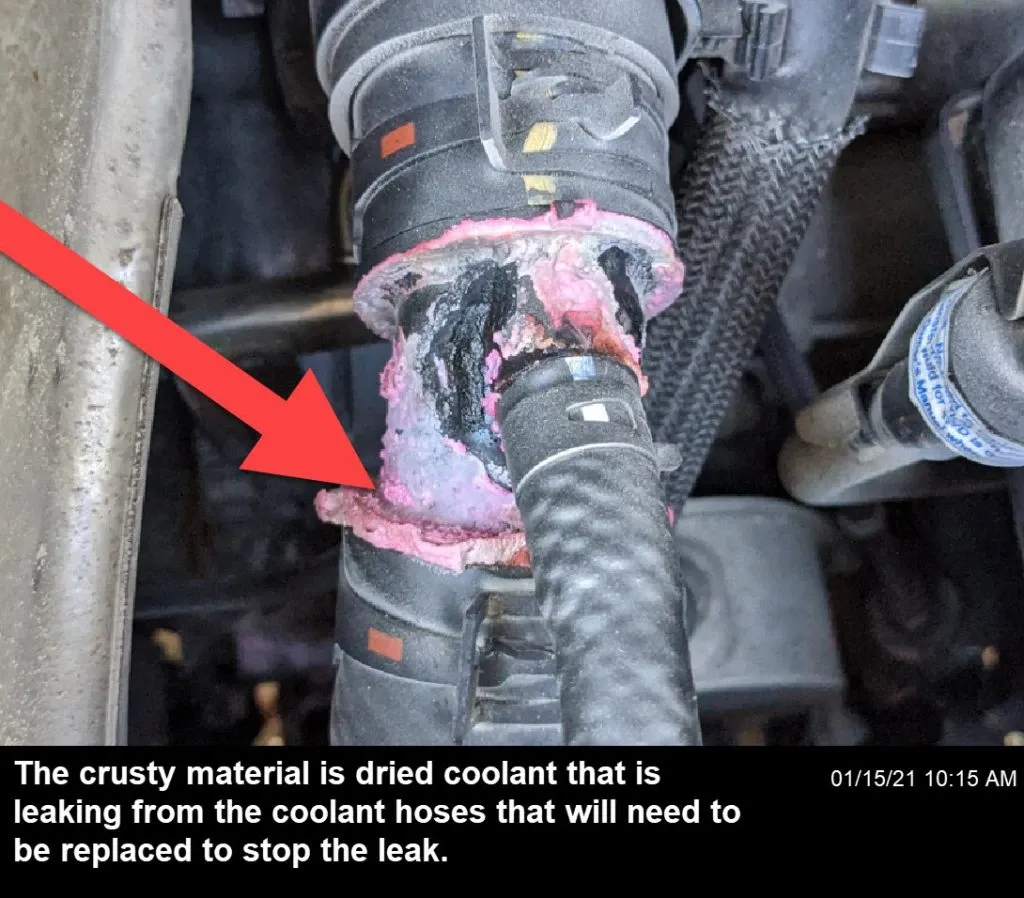

Vehicle condition: Brakes, lights, tires, hoses, fluid leaks, etc. This could range from oil leaks to coolant leaks from the radiator and more.

Cargo securement: Proper loading and tie-downs.

Documentation: Maintenance records, pre-trip inspections, etc.

You can find more details about the specific items on a DOT vehicle inspection checklist by searching online or checking with the Federal Motor Carrier Safety Administration (FMCSA) website https://www.fmcsa.dot.gov/

2. Driver Qualification File Checklist

This checklist helps ensure that a motor carrier maintains a complete and up-to-date file for each driver, as required by federal regulations. It includes items like:

-

Employment application

-

Training records

-

Medical examiner's certificate

-

Driving record

3. New Entrant Safety Audit Checklist

This checklist applies to new commercial motor vehicle companies and helps them understand and comply with safety regulations before they begin operating. It covers areas like:

-

Safety management programs

-

Driver qualification and training

-

Vehicle maintenance procedures

-

Drug and alcohol testing programs

4. General Compliance Checklist

Many companies and organizations use their own checklists to ensure general compliance with DOT regulations. These may include items from any of the above categories, depending on the specific needs of the company.

It's important to note that these are just examples, and the specific contents of a "DOT checklist" will vary depending on the context. If you're unsure which checklist is relevant to your situation, it's best to consult with a qualified professional or the relevant DOT or FMCSA regulations.

What are common DOT violations?

Here are some of the most common DOT violations categorized by area:

Driver Qualification Violations

-

Non-English speaking driver: This driver only inspection focuses on the driver's communication. Operating a commercial motor vehicle (CMV) without the ability to communicate effectively in English.

-

Operating a CMV without a CDL: Driving a CMV without the required Commercial Driver's License (CDL).

-

Driver exceeding the allowable hours of service (HOS): Exceeding the maximum number of hours a driver can operate a vehicle without taking mandatory rest breaks.

Vehicle Maintenance Violations

-

Not having required operable lights: Missing or malfunctioning headlights, taillights, brake lights, and other required lighting.

-

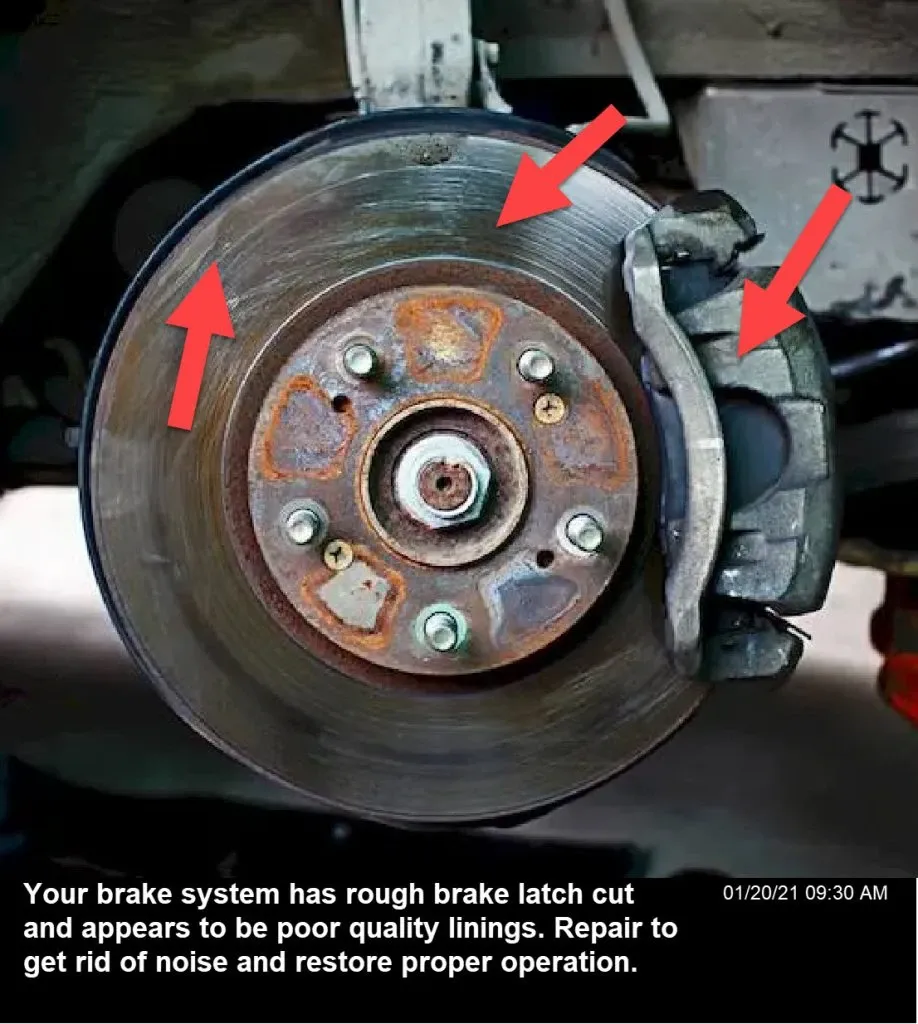

Parts or accessories in disrepair: Cracked windshields, faulty brakes, worn tires, etc., that can compromise vehicle safety.

-

Leaking fluids: Visible leaks of oil, coolant, or other fluids can indicate potential engine or brake problems.

Moving Violations

-

Speeding: Exceeding the posted speed limit.

-

Following too closely: Failing to maintain a safe following distance from the vehicle in front.

-

Improper lane changes: Changing lanes without signaling or checking blind spots.

-

Reckless driving: Operating a vehicle in a way that endangers the safety of others.

-

Failure to yield to the right of way: Disobeying traffic signals or signs that require yielding to other vehicles or pedestrians.

Hours of Service Violations

-

Form and manner issues: Incorrectly filling out or maintaining required logs regarding driving time and breaks.

-

Driver not in possession of required records: Failing to carry mandatory documents like the driver's CDL, medical card, and logbook.

Other Common Violations

-

Failing to implement a drug and alcohol testing program: Carriers are required to have a program in place to test drivers for drug and alcohol use.

-

Failing to maintain ELD instruction sheet: Electronic Logging Devices (ELDs) require specific instructions for drivers, which need to be readily available.

-

Portable ELD not mounted properly: Portable ELDs must be mounted in a fixed position and visible to the driver.

- Out-of-date paper or electronic log books: If the log books are not up-to-date, either on paper or on an electronic log channel, the transportation will register a violation.

It's important to note that this is not an exhaustive list, and specific regulations and common violations can vary depending on the type of CMV and the jurisdiction. Always refer to the official DOT regulations or consult with a transportation safety professional for the latest and most accurate information. Make sure you're keeping up with inspection schedules and relying on certified mechanics to keep your truck up to standards.

How often does DOT require load-securing devices to be inspected?

The DOT requires load-securing devices to be inspected at specific intervals, as outlined in the Federal Motor Carrier Safety Administration (FMCSA) regulations:

- Within the first 50 miles after beginning a trip: This initial inspection is crucial to ensure that the cargo and securing devices haven't shifted during the initial loading and acceleration phase.

- Every 3 hours or 150 miles, whichever comes first: During the journey, regular checks are necessary to identify any potential loosening, damage, or malfunction of the securing devices.

- At any duty change: When a driver changes shifts and leaves duty status, the new driver should also conduct a thorough inspection of the cargo and securing devices to ensure continued safety.

Remember, these are the minimum requirements to fit in a commercial vehicle safety alliance. It's always recommended that drivers inspect their cargo and securing devices more frequently, especially when driving in harsh weather conditions, over rough roads, or for extended periods.

Here are some additional points to keep in mind:

- Drivers are responsible for ensuring their cargo is properly secured and complying with all DOT regulations.

- The specific type of securing devices required depends on the type of cargo being transported. For example, the inspection for radioactive shipment is a lot more investigative and thorough.

- Drivers should be trained on how to properly inspect and use cargo-securing devices.

Do I need a DOT inspection in Texas?

It depends. While both USDOT and TxDOT are related to transportation in the United States, they serve different purposes and have different jurisdictions. Let's explore that in detail.

USDOT (United States Department of Transportation):

- Federal agency: Oversees transportation safety and infrastructure development across the entire United States.

- Responsibilities:

- Sets national standards for vehicle safety, driver qualifications, and commercial motor vehicle operations.

- Issues USDOT numbers to commercial motor carriers operating interstate (across state lines).

- Conducts safety inspections of commercial motor vehicles through the Federal Motor Carrier Safety Administration (FMCSA).

- Provides funding and technical assistance to states for transportation projects.

TxDOT (Texas Department of Transportation):

- State agency: Responsible for transportation infrastructure and safety within the state of Texas.

- Responsibilities:

- Maintains state highways and bridges.

- Sets intrastate (within state) transportation regulations for Texas, which may be more stringent than federal standards.

- Issues TxDOT numbers (also known as TxDMV numbers) to commercial motor vehicles operating solely within Texas.

- Conducts safety inspections of intrastate commercial motor vehicles.

In essence:

- USDOT: This is a North American standard inspection on commercial vehicles. This applies to all commercial motor vehicles operating interstate and sets national standards.

- TxDOT: Applies only to commercial motor vehicles operating solely within Texas and may have additional regulations within the state.

Important points to remember:

- Most motor carriers require both USDOT and TxDOT numbers if they operate interstate and intrastate in Texas.

- TxDOT number is not a substitute for a USDOT number for interstate operations.

- Other states besides Texas have state-only DOT regulations. So, ensure you're considering the regulations of the state you'll work with.

What is the most common reason a vehicle is placed out of service?

While there's no single "most common" reason, two main categories account for a significant portion of vehicles being placed out of service during DOT inspections:

1. Brake System Violations:

- Brakes are crucial for safe vehicle operation, so any issue compromising their effectiveness can lead to an out-of-service order. This includes:

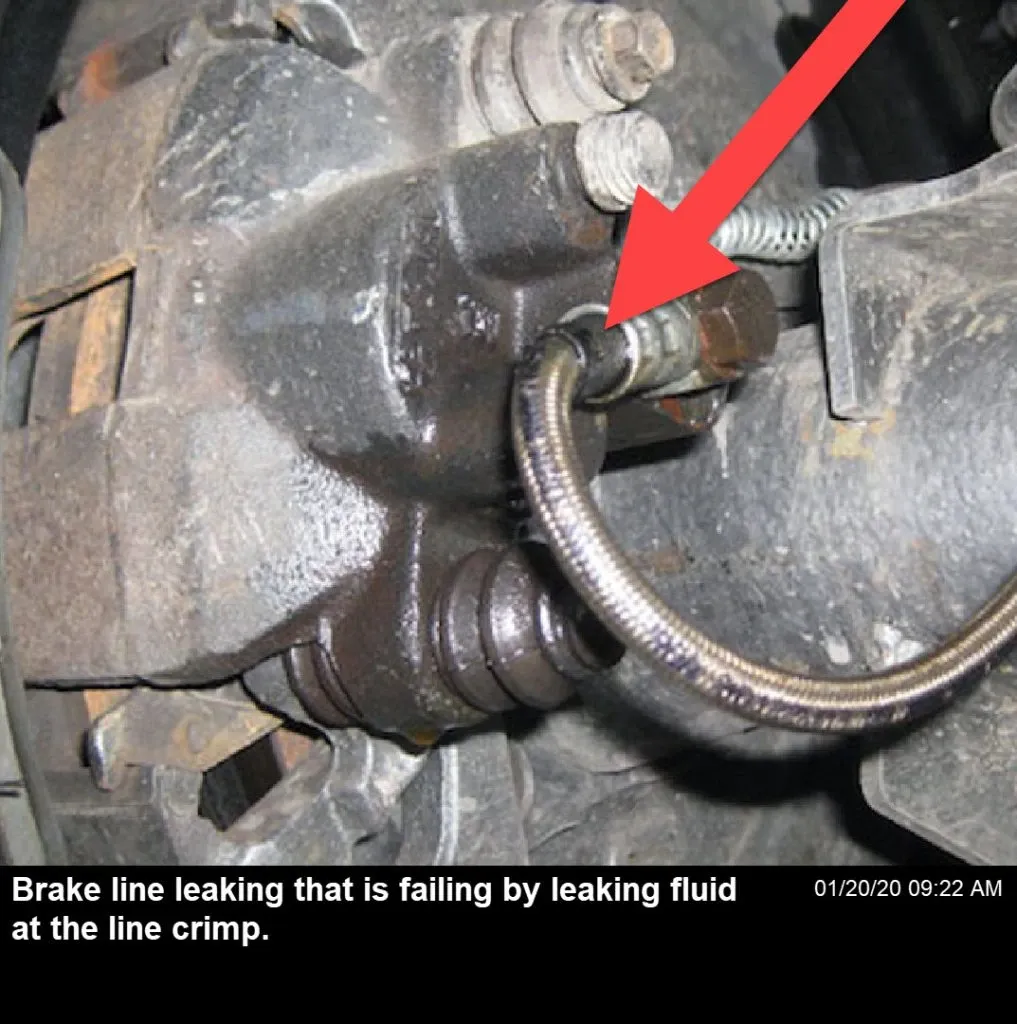

- Brake leaks: Any leakage of fluid from the brake system can indicate a malfunction or potential component failure.

- Air brake malfunction: Most commercial trucks use air brakes. So any issue in this system will be inspected and recorded.

- Worn brake pads or drums: Insufficient pad or drum thickness reduces braking power and increases stopping distance.

- Faulty brake lines: Cracks, corrosion, or damage to brake lines can compromise the system's functionality, causing leaks and affecting the brake caliper.

-

- Inadequate brake pressure: Low system pressure can lead to weak braking performance, potentially causing accidents. This often comes with a brake warning light.

2. Tire Violations:

- Tires play a vital role in safe vehicle handling and stopping ability. Issues with tires can lead to out-of-service orders, including:

- Improper tire inflation: Under-inflated or over-inflated tires can affect handling, and stability, and increase the risk of blowouts. This often triggers the tire pressure light in modern cars.

- Load range: The inspector will check if the tires are capable of enduring the truck's load; they'll typically feature load ranges.

- Wrong recaps: A DOT inspector will check if the tires have been recapped, and if the recaps happened in unsafe portions of the tire.

- Worn tire tread: Insufficient tread depth reduces grip and increases stopping distance on wet or slippery surfaces.

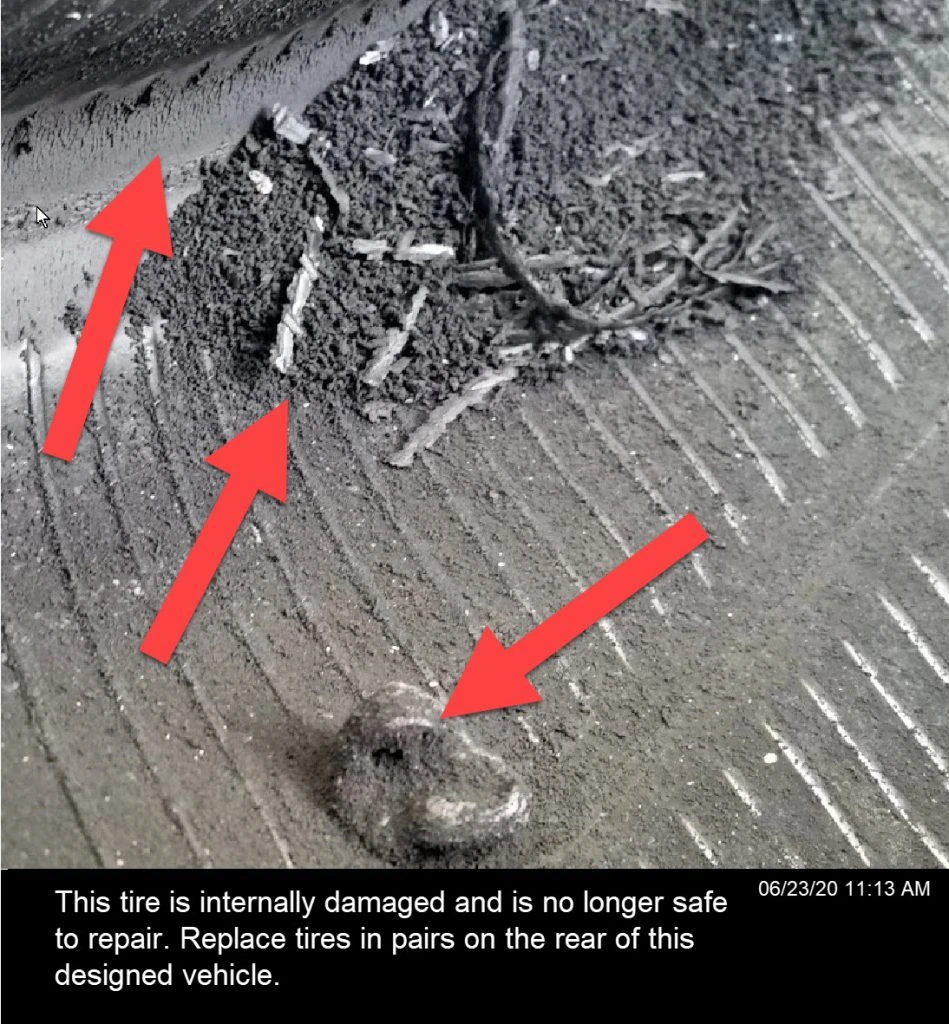

- Visible damage: Cuts, bulges, or other visible signs of damage on a tire can compromise its integrity and pose a safety risk. This includes visible internal damage during in-depth inspections; they'll often cause the tire pressure light to engage.

-

- Unbalanced tires: Tires out-of-balance, causing excess vibration on the steering wheel.

It's important to note that these are just two main categories, and several other violations can lead to an out-of-service order. These include:

- Driver qualification and drug and alcohol testing violations.

- Improper vehicle lighting.

- Cargo securement issues.

- Faulty windshield wipers or defective mirrors.

- Missing or malfunctioning safety equipment.

Remember, compliance with DOT regulations is crucial for ensuring the safety of drivers, passengers, and everyone on the road. Regular vehicle maintenance, proper driver training, and adherence to regulations are essential for avoiding out-of-service orders and potential accidents.